We present a challenge for Group of Twenty (G20) discussions that entails (1) greater awareness of the role of non-fuel minerals in the global economy overall, but specifically in the energy sector; and (2) the introduction and acceleration of alternative energy sources and technologies. We focus on chemical battery energy storage, given its prominence in all views and outlooks of energy futures, especially for mobility. We present recommendations for G20 discussions and actions on battery materials, and the crucial underlying supply chains for mineral commodities.

Challenge

There is growing interest in non-fuel minerals, such as those used as materials for battery energy storage in electric vehicle (EV) transportation and other applications. Risk and uncertainty are inherent in non-fuel mineral sourcing, supply chains, and supply–demand balances. Most non-fuel minerals are mined in economically weaker countries, many of which have fragile economies. Thus, the import reliance is high and large producers often monopolize the market. These dynamics are captured by so-called mineral “criticality,” although the definitions, criteria, and methods thereof remain inconclusive.

There is greater scrutiny of industry and governments in terms of ensuring environmental and social stewardship. There is scarce knowledge about lifecycle effects such as from the “mines to wheels.” The currently used metrics—including end-oflife management—are fragmented. Given materials inputs, it is particularly unclear if the combined lifecycle effects associated with “new” energy systems are an improvement over those associated with other conventional systems. The challenge is further complicated when we include non-fuel minerals for the full suite of industrial and human needs—that is, minerals to support life.

The present COVID-19 context adds complications. First, economic repercussions have shined a light on the brittleness of global supply chains, with calls to diversify, “re-shore,” or even build them anew.

Second, there exist idiosyncratic risks inherent to energy and minerals-related industrial operations, and companies, trade associations, and governments have been struggling to manage them. This is especially true for remote and frontier operations and/or those in emerging, developing, and fragile economies with inadequate public health capacity.

Third, many non-governmental organizations and representatives of some governments are seeking to accelerate decarbonization in order to spur economic recovery and restoration.[1] While this goal may be well intentioned, building the capacity for it entails serious obligations of taxpayer and sovereign resources. At the same time, the slack utilization and lost revenues would burden legacy energy systems, and supply chain stresses, which are already in evidence, would increase. Thus, we believe that scoping and preparation would be a better use of time and scarce resources than acceleration.

Nevertheless, the Group of Twenty, or more commonly, the G20, should recognize and address the important challenge associated with non-fuel mineral-based energy transitions as well as sustainable, resilient raw materials inputs for overall economic development and growth. As the international community continues to navigate oil supply security risks, it must shift its focus to the equally demanding security risks related to non-fuel mineral supply chains. The current COVID-19 pandemic further exacerbates the existing risks and uncertainties and is expected to create new ones. We expect these essential points to be included in G20 conversations.

Proposal

We propose five recommendations and actions for G20 engagement on non-fuel minerals for future energy pathways.

Framing: Batteries for EVs and Battery Minerals and Materials

First, energy storage is integral to all “new” energy system schemes. Second, mobility itself is complicated. This makes the electrification of transportation a useful focal point of discussion. There exist many EV options, given the market and regional diversity in which EVs are sold. However, battery capacity and performance are primary, which are a function of design and chemistry. They are a combination of minerals and materials that enable charging and release of electricity over multiple cycles while staving off degradation. Mobility has additional constraints of battery weight, safety, and other characteristics that make a battery design more or less favorable.

For some EV models, the batteries constitute two-thirds to one-half of the entire purchase cost. The lifetime cost of an EV also includes battery replacement, raising questions of after-market value. However, the perceptions that batteries are “cheap” make EVs attractive. The falling costs of batteries can be attributed to the prevailing commercial lithium-based chemistry—where 60–70% of capacity comes from China. Changes in battery chemistries, along with relocation and diversification of battery production, bear implications for costs. Re-engineering batteries and their supply chains would further affect labor markets and trade balances, raising attendant questions.

Countries with the largest light-duty fleets face the toughest hurdles for adoption. EV batteries must meet performance criteria for consumer acceptance. EVs are not likely to be successful as “standalone” products if they are not affordable and desirable without public (government) support to close the gap between customer preferences and performance.

Governments across jurisdictions and at different levels of governance are devising policy/regulatory pushes to encourage, or even enforce, the electrification of transport (Foss and Zoellmer 2020). A common approach is to propose bans on conventional internal combustion engine (ICE) vehicles, or at least on the on sales of new ICE vehicles, sometimes with aggressive targets for timing. Although no government has enacted bans into law, many jurisdictions are attempting to couple EV market share targets and buildout charging infrastructure.

In this regard, “range anxiety” captures a first-order performance priority. EV customers want to travel some distance before the batteries need to be re-charged. The energy density of gasoline is still 100 times higher than that of the best lithium battery designs (Schlachter 2012). In 2016, Argonne National Laboratory estimated that pure battery EVs (BEVs) could be at par with equivalent ICE vehicles by 2045 (Vijayagopal et al. 2016; Vijayagopal, 2016). Reduced vehicle weight and enhanced aerodynamic design would further increase engine efficiency. However, battery energy density (watt hours per kilogram or W·h/kg) must advance along with motor power density (kilowatts per kilogram or kW/kg)—each metric will need to be roughly doubled, from 135 to 320 W·h/kg and 8.6 to 16 kW/kg, respectively.

Battery science is moving toward “sustainable” battery chemistry to achieve improvements. Such advances are likely to include new chemistries for responsive battery management systems (new sensors with better state of health measurements), better understanding of degradation, and new designs (e.g., redox flow batteries) that could be commercialized. However, commercial scaling is a hurdle.

Lithium, the preferred material for cathodes, is alluring for many reasons—mainly its low weight and high specific energy. Grey (2019) discusses that leading battery scientists believe that basic re-designs are needed to obtain better energy density relative to weight and thus prolong battery life, but the drive to improve performance puts battery safety at risk.

Lithium is reactive, whereas cobalt improves stability. However, sensitivities around cobalt extraction and supply have triggered a broader search for substitutes. Attempts to store more energy in lithium batteries increase the risks associated with overcharging, overheating, short circuits, and other hazards. Lithium batteries are also hazardous materials for shipping and cargo safety.

We also know that battery manufacturing is itself energy-intensive. Depending on the energy source, battery production may be emissions-intensive too. According to one early estimate, the assembly of a typical lithium battery requires 400 kW·h of energy for every 1 kW·h of energy with 75 kg of CO2 released (Grey 2019). Recent reviewers report higher values—nearly 500 kg of CO2 per kW·h of battery capacity (Ambrose and Kendall 2016). Thus, a “Gigafactory” capable of, say, 24 GW·h of battery manufacturing could produce upward of 13 million metric tons of CO2 per year. In comparison, all electronics manufacturing in the U.S. in 2017 produced 6 MMT.[2]

Beyond manufacturing, lifecycle effects also involve shipping, vehicle assembly, electricity sources for recharging, and end-of-life disposal and recycling. Manufacturing inputs also entail the lifecycle effects of mining and mineral processing as well as the associated supply chains. Thus, it is expected that there is greater acceptance now of recycling batteries and other components as a prerequisite for sustainable transition to electrified transportation (Messagie 2017).

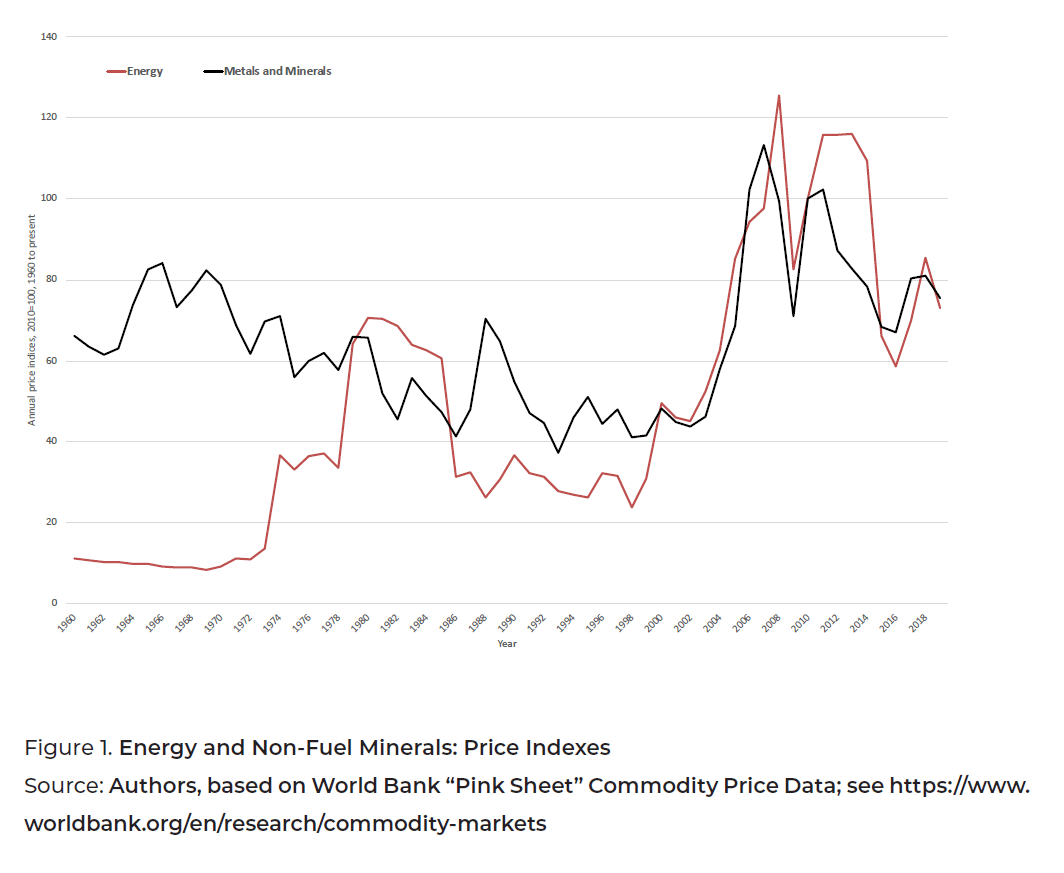

The importance of linking energy and non-fuel minerals in strategic decision-making about energy systems cannot be overstated. As shown in Figure 1, oil disruptions in the late 1960s through mid-1970s forced the convergence of energy and non-fuel mineral commodities. The prices for energy fuels are a cost input for non-fuel minerals and materials, and vice versa. Further, mineral extraction and processing are energy-intensive, whereas energy production and delivery are resource-intensive. Thus, convergence across commodities markets, supply chains, and prices implies that the demand for minerals and materials for battery energy storage bear enormous implications for all industrial systems and activity worldwide.

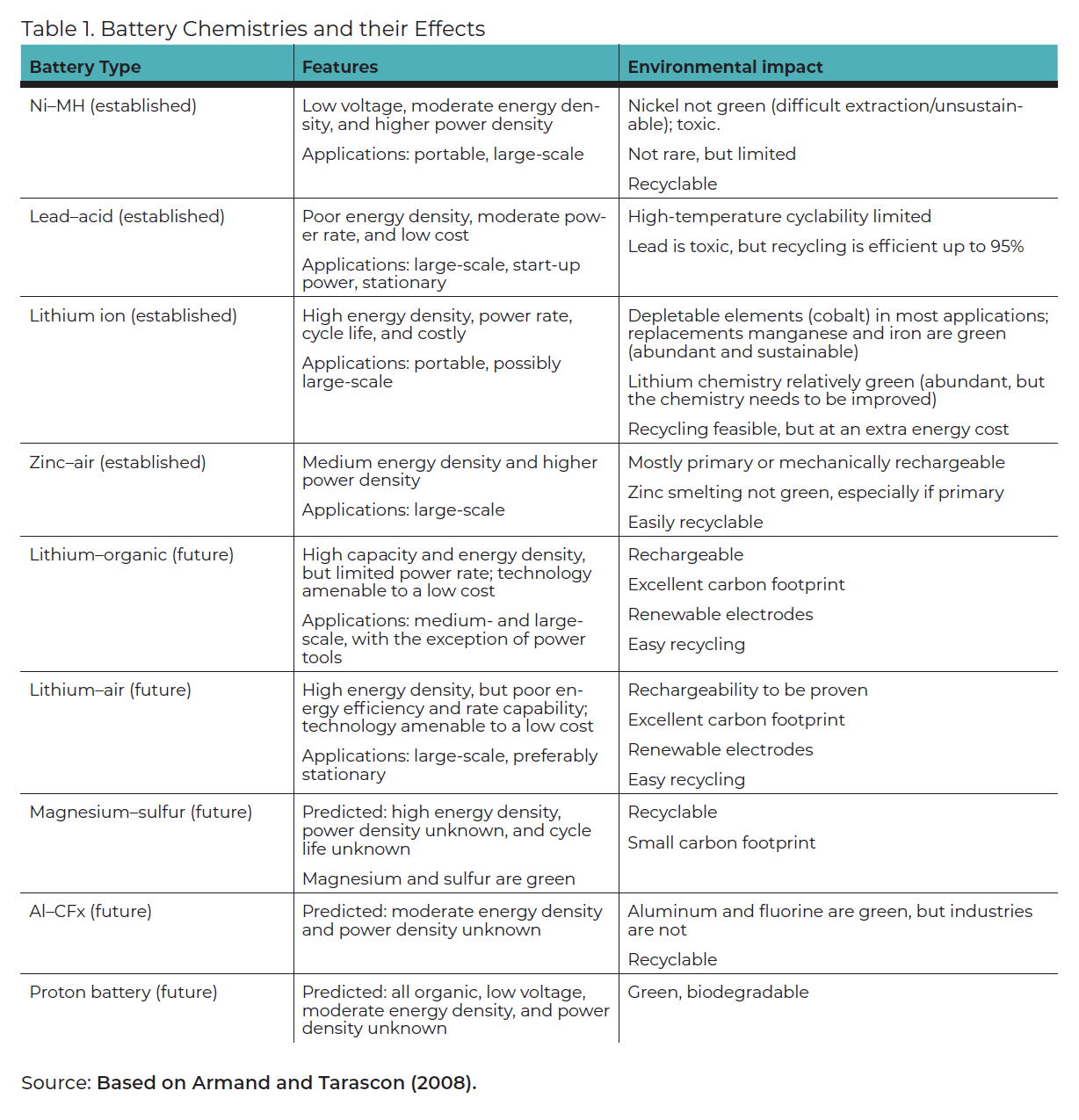

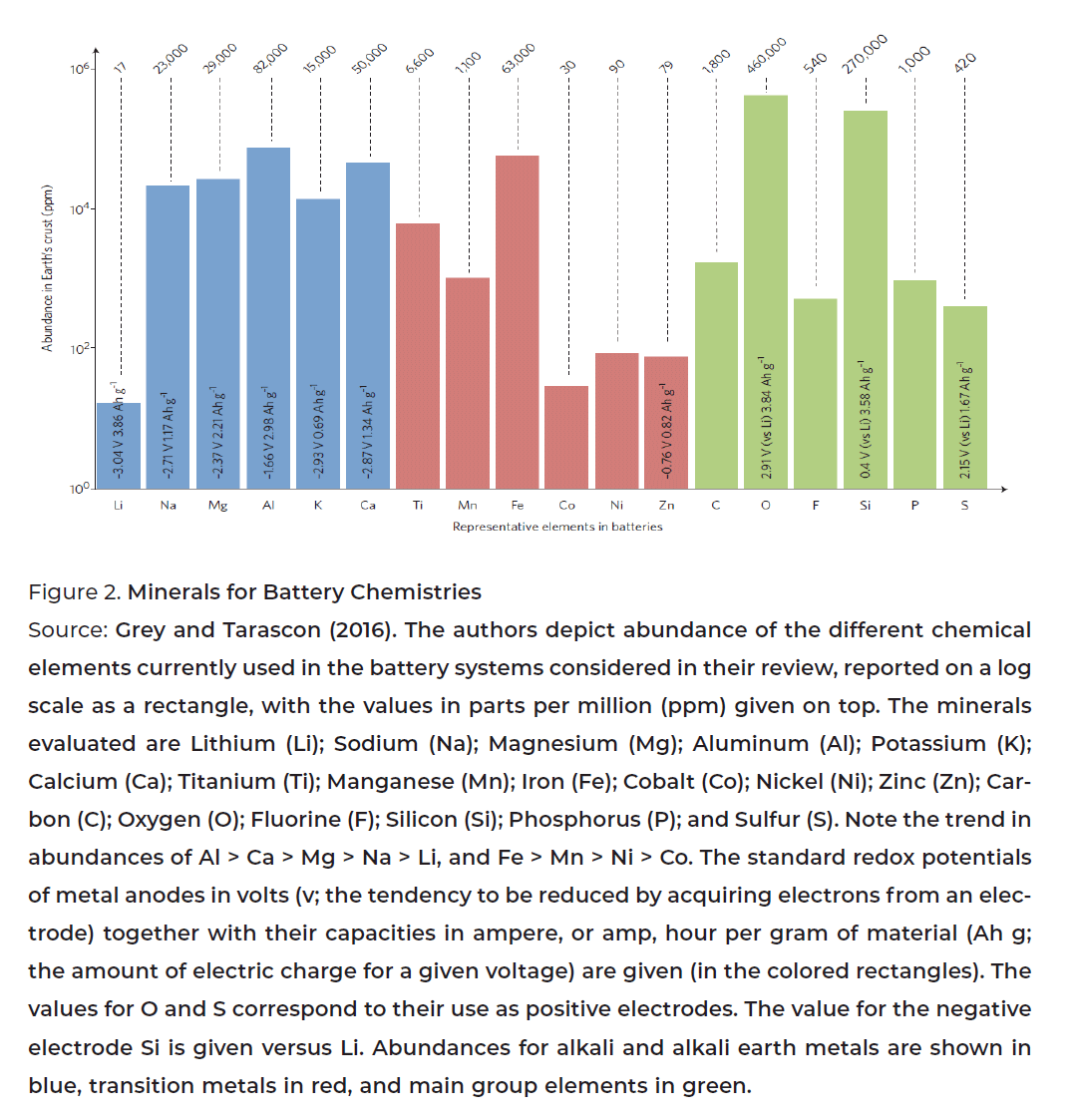

Minerals and materials inputs for batteries have been extensively reviewed. An early, prominent study by Armand and Tarascon (2008) offers a succinct summary of battery designs and environmental considerations (see Figure 2). Every mineral commodity that may be used to improve battery performance presents trade-offs across a number of metrics, including extractive processes and toxicity.

Table 1. Battery Chemistries and their Effects

Grey and Tarascon (2016) further examine minerals for battery chemistries (see Figure 2), and find that resource abundance explains only a part of the phenomenon. To build sustainable, resilient raw materials supply chains, commercial interests must have access to sometimes-remote resources, engage in extraction using best practices, build facilities for refining and processing, and build logistics for shipping to manufacturing points. Further, the quality of the ore grade and refined, processed product take primacy. Not all minerals are subject to open, transparent trade and pricing—indeed, few of them are. “Liquidity” or market depth (number of participants and financial flows) to support open, transparent trade and pricing could be expanded, but only if barriers to resource access are reduced, robust supply chains are built, and competitive procurement with price discovery are employed. Any variability in these and many other conditions results in a most uneven global playing field for both established minerals commodities as well as specialty minerals for advanced technologies and uses. The most typical mineral criticality indicators reflect internal, domestic imperatives of home governments ignoring many other parameters.[3]

Rapid development of battery materials depends on primary feedstocks

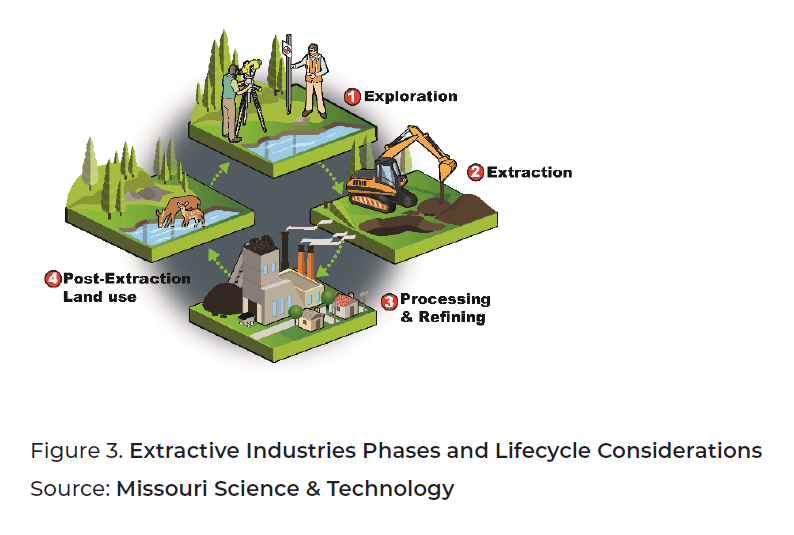

Examples of battery materials that are dependent on primary feedstocks are nickel, cobalt, lithium, and other energy critical materials (see Bauer et al. 2010). Mining and mineral processing phases and the “upstream” lifecycle (see Figure 3) would bear the brunt in this case. Environmental, governance, and lifecycle risks and uncertainties require mitigation. Further, industry activities affect host communities, generating “boom and bust” economic conditions, competition for natural resources such as land and water, and other effects that could foster opposition to development. Given these issues, cobalt has quickly emerged to epitomize battery dependency on extractive industries. For example, Frankel (2016) chronicles the ethical and environmental issues of cobalt mining in the Democratic Republic of Congo, which provides more than 50% of global cobalt supplies from primary extraction (United States Geological Survey 2017). Frankel (2016) further notes:

“The challenge is how to ensure that this workforce understands the consequences to ecological and social systems of the design choices they make at each stage of the material’s life cycle.”

Experts working at various points along the materials lifecycle seldom apply lifecycle assessment (e.g., International Organization for Standardization 2006) and similar decision-making theories (Awuah-Offei and Adekpedjou 2011). Even as resource extraction companies improve stakeholder engagement, ever-changing societal expectations cause continued conflicts between stakeholders and resource developers (Hodge 2014). Indeed, good environmental management and community engagement that lead to shared value yield more sustainable primary extraction (Porter and Kramer 2011).

Finally, Ali et al. (2017) note:

“Technological evolution needs to be reinforced by establishing global practices that balance mining and mineral treatment with biodiversity protection, agriculture and urbanisation, and other land and water uses. Good environmental practice, proactive and effective stakeholder engagement, and co-existence of mining and other land uses must form the basis of sustainable mineral exploitation. To achieve this, better coordination between industry and governments will be needed.”

In summary, battery energy storage represents a significant source of new demand for non-fuel minerals. We must improve public domain transparency in emerging battery designs and chemistries along with related materials requirements. However, intellectual property considerations should gain priority as well, as they pertain to economic and trade discussions. Transparent, publicly accessible mineral production data are crucial for effective decision-making and policymaking. Numerous such databases already exist,[4] as do international forums that provide transparency in mineral production and availability as well as independent surveys.[5] We need a better understanding of energy and emissions intensities for more complete appreciation of, and appropriate public policy and regulatory responses to, the consequences of energy transition policies and imperatives.

The G20 should not consider itself immune to the urgency of better preparing future generations of engineers and scientists for the complete mines to wheels supply chain lifecycle, and the equivalent for other energy and non-energy applications. This would help to achieve secure and sustainable use of our precious, dwindling resources. Industry, government, and research and education community experts require better understanding of lifecycle analyses, consequences, and management.

Recommendations and Actions

Recommendation 1: Include non-fuel minerals in G20 discussions. The G20 should issue a public statement recognizing the criticality of non-fuel minerals for the global economy and future energy pathways. The G20 member countries should:

- Provide reliable public domain information on non-fuel mineral resource assessments and production, criticality determinations and methodologies, trade flows, and energy and non-energy industrial applications;

- Establish a portal for convening country data sources and links;

- Incorporate key minerals market dynamics into crosscutting economic discussions;

- Foster transparency in energy and emissions intensities of mineral extraction, processing, and battery manufacturing; and

- Recognize in policy summaries and statements the importance of open, free, competitive, and international trade in minerals and materials.

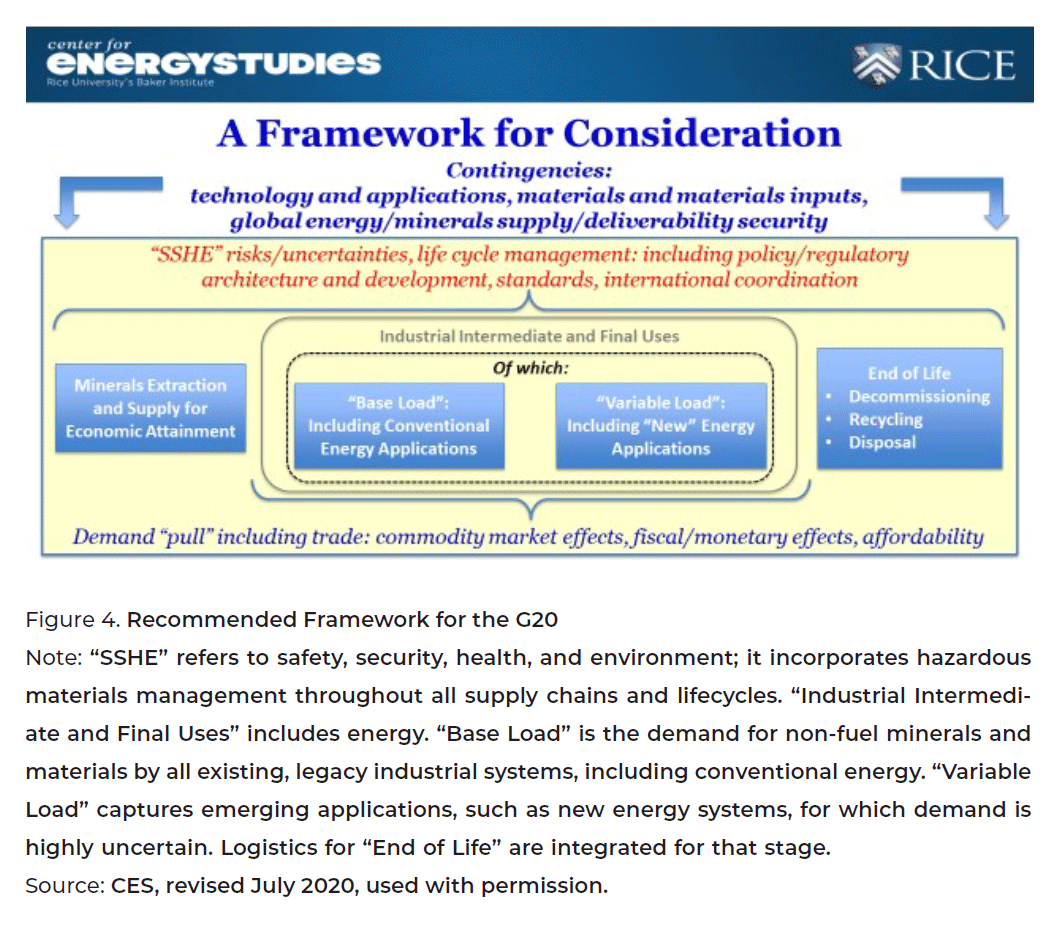

- Finally, we also suggest a framework, as shown in Figure 4, for G20 discussions, recommendations, and actions as well as for ongoing monitoring.

Recommendation 2: The G20 should fund research to develop a uniform mineral criticality index that combines sustainability, supply chain risk, and cost-reflectiveness of each member nation’s unique situation.

- G20 members should encourage research to scope and define common metrics for criticality and, thus, foster international cooperation for common approaches; and[6]

- The G20 should foster exchanges among and between countries, industries, and research communities to facilitate and advance research concepts.

Recommendation 3: The G20 should commit to promote the transparency of critical mineral production data, processing, and technology within and beyond its member countries. Thus, the G20 member countries should:

- Emphasize on reliable, high-level, publicly accessible data as critical to good decision-making and policymaking;

- Encourage replication of successful examples; and

- Engage international forums that provide transparency in mineral production and availability.

Recommendation 4: The G20 should engage relevant multilateral agencies to foster technical collaborations. In this regard, key disciplines include geoscience, political science, economics, and engineering (mining, metallurgical, geological, environmental, and systems). The common stakeholders include governments, global aid agencies, and non-governmental organizations. Collaborations should foster analysis, build capacity, provide technical knowledge, and empower decision-makers in resource-rich developing countries to sustainably develop critical mineral resources. Thus, the G20 members should:

- Encourage technical collaborations that target countries lacking in capacity to manage and sustainably develop major deposits of critical mineral resources;

- Encourage members with significant expertise to share knowledge on mineral policy and science and technology for sustainable development of critical mineral resources (including minimizing environmental and social effects of mining);

- Support the World Bank’s Climate Smart Mining initiative[7] to help resource-rich developing countries benefit from the increasing demand for minerals and metals, while ensuring their mining sectors are managed in a way that minimizes the environmental and climate footprint; and

- Use networks such as the U.S. Department of Energy National Laboratories and Technology Centers for fostering collaboration among and between government, industry, and research communities for basic and advanced research and development, expanding capacity for minerals and materials, and assisting with capacity building elsewhere in the world.

Recommendation 5: The G20 should commit to sharing the best practices for the extraction and recovery of critical minerals. Thus, the G20 members should:

- Join the governments of, for example, Australia, Botswana, Canada, Peru, and the U.S. in the Energy Resource Governance Initiative to disseminate best practices.[8]

- Engage the mining industry through the Global Mining Guidelines Group.[9]

Disclaimer

This policy brief was developed and written by the authors and has undergone a peer review process. The views and opinions expressed in this policy brief are those of the authors and do not necessarily reflect the official policy or position of the authors’ organizations or the T20 Secretariat.

References

Ali, Saleem H., Damien Giurco, Nicholas Arndt, Edmund Nickless, Graham Brown,

Alecos Demetriades, Ray Durrheim, et al. 2017. “Mineral Supply for Sustainable Development

Requires Resource Governance.” Nature 543, no. 7645 (March): 367. https://doi.org/10.1038/nature21359.

Ambrose, Hanjiro, and Alissa Kendall. 2016. “Effects of Battery Chemistry and Performance

on the Life Cycle Greenhouse Gas Intensity of Electric Mobility” Transportation

Research Part D 47 (August): 182–194. https://doi.org/10.1016/j.trd.2016.05.009.

Armand, Michel, and J-M. Tarascon. 2008. “Building Better Batteries.” Nature 451, no.

7179 (February): 652–657. https://doi.org/10.1038/451652a.

Awuah-Offei, Kwame, and Akim Adekpedjou. 2011. “Application of Life Cycle Assessment

in the Mining Industry.” The International Journal of Life Cycle Assessment 16,

no. 1 (January): 82–89. https://doi.org/10.1007/s11367-010-0246-6.

Bauer, Diana, David Diamond, Jennifer Li, Michael McKittrick, David Sandalow, and

Paul. 2010. “Critical Materials Strategy.” U.S. Department of Energy. https://www.energy.gov/sites/prod/files/DOE_CMS2011_FINAL_Full.pdf.

Blengini, Gian Andrea, Philip Nuss, Jo Dewulf, Viorel Nita, Laura Talens Peirò, Beatriz

Vidal-Legaz, Cynthia Latunussa et al. 2017. “EU Methodology for Critical Raw

Materials Assessment: Policy Needs and Proposed Solutions for Incremental Improvements.”

Resources Policy 53 (September): 12–19. https://doi.org/10.1016/j.resourpol.2017.05.008.

Fortier, Steven M., Nedal Nassar, Graham Lederer, Jamie Brainard, Joseph Gambogi,

and Erin McCullough. 2018. “Draft Critical Mineral List—Summary of Methodology

and Background Information—U.S. Geological Survey Technical Input Document in

Response to Secretarial Order No. 3359.” United States Geological Survey Open-File

Report No. 2018-1021. https://doi.org/10.3133/ofr20181021.

Foss, Michelle Michot, and Katherine Zoellmer. 2020. “Will Electric Vehicles Transform

Electricity Distribution Networks? Only Time will Tell.” IAEE Energy Forum /

Second Quarter. https://www.iaee.org/en/publications/fullnewsletter.aspx?id=103.

Frankel, Todd C. 2016. “The Cobalt Pipeline: Tracing the Path from Deadly Hand-Dug

Mines in Congo to Consumers’ Phones and Laptops.” Washington Post, September

30, 2016. https://www.washingtonpost.com/graphics/business/batteries/congo-cobalt-mining-for-lithium-ion-battery.

Fu, Xinkai, Adriano Polli, and Elsa Olivetti. 2019. “High‐Resolution Insight into Materials

Criticality: Quantifying Risk for By‐Product Metals from Primary Production.” Journal

of Industrial Ecology 23, no. 2 (March): 452–465. https://doi.org/10.1111/jiec.12757.

Grey, C. 2019. “The Super Batteries Challenge: The Devil is in the (Chemistry/Materials)

Detail.” Presentation at Rice University/Imperial College Workshop on Energy

& Minerals, Framing Integration Futures, September 18–19, 2019, Center for Energy

Studies, Rice University’s Baker Institute for Public Policy.

Hodge, R. Anthony. 2014. “Mining Company Performance and Community Conflict:

Moving Beyond a Seeming Paradox.” Journal of Cleaner Production 84 (December):

27–33. https://doi.org/10.1016/j.jclepro.2014.09.007.

International Organization for Standardization. 2006. “ISO 14040:2006 Environmental

Management — Life Cycle Assessment — Principles and Framework Vol. 3.” ISO/

TC 207/SC 5 Life Cycle Assessment. https://www.iso.org/standard/37456.html.

McFarlane, Sarah. 2020. “Governments Eye a Green Economic Recovery. Some Industries

Aren’t Convinced.” Wall Street Journal, July 7, 2020. https://www.wsj.com/articles/governments-eye-a-green-economic-recovery-some-industries-arent-convinced-11594113028?mod=searchresults&page=1&pos=5.

Messagie, Maarten. 2017. “Life Cycle Analysis of the Climate Impact of Electric Vehicles,

Transport and Environment.” VUB MOBI Mobility, Logistics & Automotive Technology

Research Centre. https://www.transportenvironment.org/sites/te/files/publications/TE%20-%20draft%20report%20v04.pdf.

Moats, M., A. Filzwieser, S. Wang, W. Davenport, T. Robinson, and A. Siegmund. 2019.

“Global Survey of Copper Electrorefining: 2019 World Tankhouse Operating Data.”

Proceedings of the 58th Annual Conference of Metallurgists (COM), 10th International

Copper Conference, Copper, Vancouver, Canada, August 18–21, 2019.

Nassar, Nedal T., Jamie Brainard, Andrew Gulley, Ross Manley, Grecia Matos, Graham

Lederer, Laurence R. Bird, et al. 2020. “Evaluating the Mineral Commodity Supply Risk

of the U.S. Manufacturing Sector.” Science Advances 6, no. 8 (February): eaay8647.

https://doi.org/10.1126/sciadv.aay8647.

Porter, Michael E., and Mark R. Kramer. 2011. “Creating Shared Value.” In Managing

Sustainable Business, 323–346. Dordrecht: Springer.

Schlachter, Fred. 2012. “Has the Battery Bubble Burst?” APS News 21, no. 8, August/

September. https://www.aps.org/publications/apsnews/201208/backpage.cfm.

Sonnemann, Guido, Eskinder Demisse Gemechu, Naeem Adibi, Vincent De Bruille,

and Cécile Bulle. 2015. “From a Critical Review to a Conceptual Framework for Integrating

the Criticality of Resources into Life Cycle Sustainability Assessment.” Journal

of Cleaner Production 94 (January): 20–34. https://doi.org/10.1016/j.jclepro.2015.01.082.

Vijayagopal, Ram. 2016. “Comparing the Powertrain Energy and Power Densities of

Electric and Gasoline Vehicles.” Presentation at Powertrain Strategies for the 21st

Century, University of Michigan Transportation Research Institute, July 20, 2016.

https://www.umtri.umich.edu/powertrain-strategies-21st-century-1.

Vijayagopal, Ram, Kevin Gallagher, Daeheung Lee, and Aymeric Rousseau. 2016.

“Comparing the Powertrain Energy Densities of Electric and Gasoline Vehicles).” SAE

Technical Paper 2016-01-0903. https://doi.org/10.4271/2016-01-0903.

Appendix

[1] . McFarlane (2020) reports that governments have committed to roughly $12 trillion in recovery stimulus worldwide—of this, about $583 billion is marked for “climate friendly” initiatives, and of this amount, $40 billion has already been funded and another $14 billion has been earmarked for EVs. General Motors alone has announced a $20 billion capital investment target, set over several years, to accelerate production of its battery-operated EV fleet. This investment would include support for U.S. supply chains, battery manufacturing, and labor (communication with GM senior personnel, March 3, 2020).

[2] . See https://www.epa.gov/sites/production/files/2018-10/documents/electronics_manufacturing_2017_in_dustrial_profile.pdf.

[3] . Examples of different critical materials lists as well as definitions are found in Nassar et al. (2020) and Sonnemann et al. (2020). See also the U.S. Department of Commerce’s strategic report A Federal Strategy to Ensure Secure and Reliable Supplies of Critical Mineral, Bauer et al. (2010), Fortier et al. (2018), Blengini et al. (2017), and Fu, Polli, and Olivetti (2019).

[4] . United States Geological Survey Minerals Commodity Summaries are published annually; see https:// www.usgs.gov/centers/nmic/mineral-commodity-summaries. Minerals UK provides a similar service; see https://www.bgs.ac.uk/mineralsuk/. The World Mining Data site is maintained by the Government of Austria under the auspices of the International Organizing Committee for the World Mining Congresses; see https://www.world-mining-data.info/. These, and other, sources vary in their mineral coverage.

[5] . Two of these include the International Copper Study Group: World Copper Factbook 2019 (see https:// www.icsg.org/index.php/component/jdownloads/finish/170/2965) and the Extractive Industries Transparaency Initiative, which deals with government revenue, but is a good example of international collaboration on transparency (see https://eiti.org/). Moats et al. (2019) offer independent data collection and dissemination. Without the participation and disclosure of mineral-producing and -processing operators and countries, there will always be significant missing data from some geographical locations. Further, technical studies that do close such data gaps tend not to be widely publicized outside of technical communities.

[6] . Examples of different critical materials’ lists and definitions are found in Nassar et al. (2020) and Sonnemann et al. (2020). The U.S. Department of Commerce released the strategic report A Federal Strategy to Ensure Secure and Reliable Supplies of Critical Mineral. Also see Fortier et al. (2018), Blengini et al. (2017), Fu et al. (2019).

[7] . See,https://www.worldbank.org/en/topic/extractiveindustries/brief/climate-smart-mining-minerals-for-climate-action.

[8] . See https://ergi.tools.

[9] . See https://gmggroup.org.