Batteries are critical components in an energy transition to a climate- neutral economy and towards achieving the Paris Agreement and United Nations Sustainable Development Goals (SDGs). The global demand for lithium batteries is expected to reach US$99.98 billion in 2025, with an annual growth rate of at least 25 percent. The massive battery production has consequences for the future management of limited resources and huge battery waste in the future. The Group of 20 (G20) members are major battery producers as well as battery customers. We propose a policy brief for the G20 countries to develop a circular economy of batteries (CEB) policy for energy sustainability, security and affordability.

Importance of Circular Economy and Circular Carbon Economy

The main concept of the circular economy (CE) revolutionises the classical “linear” economy (retrieve, produce and dispose) towards a “circular” approach by closing the loop of material flows, which is the basis for sustainability.1 Furthermore, the CE considers not only economic but also environmental aspects.2 It is understood that the status quo of the industrial ecosystem has consequences in creating an unsustainable situation for planet Earth.3 All the products in a CE ecosystem are designed to generate as little waste as possible, allowing all of its component components to be reused to make new products while minimising the usage of harmful or hazardous substances.

In practice, the CE has expanded into the circular carbon economy (CCE) where CE systems also focus on reducing carbon dioxide emissions that involves a utilisation or conversion of the generated CO2 from the combustion of fossil fuels.4,5 The CCE framework was among the main topics of discussion at the previous G20 2020.6 The CCE framework proposed by the G20 2020 Saudi Arabia is a comprehensive and integrated approach to managing emissions. The CCE approaches the reduction of emissions through a “4Rs” strategy: Reduce the amount of carbon entering the economy; reuse carbon as an input to create valuable feedstock and fuels; recycle carbon through the natural carbon cycle; and remove excess carbon from the atmosphere. One of the highly releasing carbon emissions, i.e. plastics manufacturing, and various mitigation methods in climate change approaches by implementing the CCE have been also addressed.7-9 The advantages of applying the CCE are manifold towards sustainability: fewer greenhouse gas emissions, healthy and fertile soils, increased economic growth, reduction in volatility in raw material prices and sustainable resources for manufacturing.8

To achieve a sustainable world, it is also important to note that other vital industries should be discussed, in particular stationary and portable electronic-related products. The use of electronic devices has rapidly been increasing and batteries play an important role. We anticipate that unmanaged battery waste will be a threat for the environment. In the light of the above discussion, it is urgent to pay special attention to this issue and therefore we focus on the CE of battery manufacturing.

Challenge

Batteries play a vital role as energy storage systems (ESS) to support the implementation of renewable energy resources, emergency power backup and electric vehicles (EVs).10 With 30 percent growth annually from 2010 to 2018, the battery market is projected to keep increasing by 25 percent annually until 2030.11 Batteries will be produced in huge quantities; thus, non-renewable materials such as lithium, nickel, cobalt and manganese will become huge concerns for the battery industry.12,13 It is anticipated a large amount of battery waste from “retired” batteries from portable electronics, stationary ESS and EVs will be formed. Moreover, battery waste is projected to be 1.6 million tons worldwide in 203014 with approximately 80 percent originating from G20 members in accordance with their economic share. These large quantities of battery production require more non-renewable materials. After a period of time, more battery waste will also be problematic; hence, these will raise supply chain sustainability and environmental concerns, respectively.

The G20 member states are among the big players in battery production and as battery customers. Concomitant to this strong relevance, to the best of our knowledge, there have been only limited concerns among G20 members to act upon these battery-focused issues. Increasing concern about developing a circular economy of batteries (CEB) and collaboration among the G20 members will solve significant environmental threats and material resources scarcity in the future. Therefore, enabling a G20-standard CEB is of paramount importance as a significant driver to meeting the Paris Agreement and United Nations Sustainable Development Goals (SDGs) 7, 8, 9, 12, 13 and 17. To establish a sustainable CEB, proper education for society, engagement and appropriate incentives for stakeholders and regulations from governments are required.

We also note that treating waste batteries, i.e. use for second-life applications and recycling, requires sufficient knowledge and technologies. Specifically, closing the loop of the CEB by recycling waste batteries encounters technological challenges since the development of battery-recycling technology is relatively slow compared with that of advanced battery production. To date, none of the existing battery-recycling technologies is perfect. Typical existing recycling technologies such as pyrometallurgy and hydrometallurgy produce hazardous gases and exhibit complex procedures, respectively. This challenge needs to be addressed to find the optimum economically efficient recycling process. Therefore, collaborative work towards efficient battery-recycling processes is necessary to make a practical impact.

In addition, we emphasise that processing batteries requires a high energy-intensive process with a minimum feed material capacity in order to achieve an economical waste battery-recycling process. As a result, a robust financial design and financial incentives are critical to overcoming the financial challenges in the early implementation programme.

Proposal

The need for immediate and urgent action against climate change is widely recognised. With more battery use in the future, it is critical to establish a sustainable CEB to ensure the battery value chain remains secure for future consumption. The G20 members, which presently account for around 85 percent of global GDP and 60 percent of the world’s population, are expected to play a key role in accelerating the international agenda on carbon emissions. The development of the CEB ecosystem is necessary in response to growing demand for batteries for electric mobility and energy/power systems. Therefore, we propose the following:

- It is essential for the G20 to develop a standard CEB framework policy and ensure each member state has CEB regulations. The regulatory framework should accommodate private sector incentives to accelerate the implementation of the CEB since these recycled materials will reduce CO2 emissions from battery production by 38 percent and could initiate the establishment of a green battery industry. In the near term, a detailed assessment to identify the battery-recycling target would be the key recommendation for the G20 to undertake.

- The G20 member states should establish specific protocols for battery-recycling processes from collecting used batteries to material recovery since a CEB policy would trigger new industries and players, especially in the informal sector.

- The G20 member states should encourage transparency in finance and investment data to help increase transparency and build investor confidence. This would enable incentives for key players in the battery industry and support the G20 agenda to meet the battery-recycling target through support from the financial sector.

- The G20 member states should create platforms for collaboration and sharing technology. These would also cover the training and capacity-building programmes to integrate safety, financial and business aspects in battery recycling projects.

G20 CEB FRAMEWORK POLICY

The CEB policy should collaboratively be developed by the G20 members as they comprise the largest miners, battery producers and consumers (combined). The majority of the G20 countries have their own capabilities, expertise and potential markets (Table 1). For example, countries like Indonesia, the largest nickel laterite producer, should create a sustainable mining process to ensure a sustainable nickel supply. Countries like China and the United States, with the technology and a significant market share of EVs (or BESS, battery energy storage systems), could be the centre of manufacturing, research and recycling in their regions. Countries that could implement the regulation with stringent implementation could become the role models to others in developing public awareness and implementing the regulation.

Table 1. Mapping of potential role and collaboration of CEB among the G20 countries

| No | Country | Country’s percentage of total world resources | Mining | Refining | Policies for ECB | Battery research based on technology readiness level | EV Projection 2030 | Prospective role in battery industry | |||

| Sulfidic deposits – (million tons) | Lateritic deposits – (million tons) | Low: On Development Medium: Available Stringent: Implemented | Low: TR 1-5 Medium: TR 6-7 Advanced: TR 8-10 | Low: < 10 mio Medium: < 25 mio High: > 25 mio | |||||||

| 1 | Argentina | 19 | 0 percent | – | Available | Available | Low | ||||

| 2 | Australia | 11.878.500 | 10 percent | 1.529.000 | 1 percent | Available | Available | Medium | Advanced | ||

| 3 | Brazil | 1.617.500 | 1 percent | 14.824.200 | 8 percent | – | – | Low | Low | ||

| 4 | Canada | 21.923.100 | 19 percent | – | 0 percent | – | – | Stringent | Medium | ||

| 5 | China | 6.002.000 | 5 percent | – | 0 percent | – | – | Medium | Advanced | High | Recycling Center for Asia Research and Development |

| 6 | France | 0 percent | 0 percent | – | – | Medium | |||||

| 7 | Germany | 0 percent | 0 percent | – | – | Stringent | High | Recycling Center for European Policy and Regulation model | |||

| 8 | India | – | 0 percent | 1.993.000 | 1 percent | – | – | Low | Low | ||

| 9 | Indonesia | – | 0 percent | 33.291.000 | 19 percent | Low | Low | Center of Sustainable Mining | |||

| 10 | Italy | 0 percent | 0 percent | – | – | Low | |||||

| 11 | Japan | 0 percent | 0 percent | – | – | Medium | |||||

| 12 | Republic of Korea | 0 percent | 0 percent | – | – | Stringent | Advanced | Research and Development | |||

| 13 | Mexico | 0 percent | 0 percent | – | – | Low | |||||

| 14 | Russia | 20.457.500 | 17 percent | 3.960.500 | 2 percent | Available | Available | Medium | Medium | ||

| 15 | Saudi Arabia | 0 percent | 0 percent | – | – | Low | |||||

| 16 | South Africa | 33.216.300 | 28 percent | – | 0 percent | – | – | Low | Medium |

| 17 | Turkey | 0 percent | 1.075.200 | 1 percent | – | – | Low | Medium | |||

| 18 | The United Kingdom | 0 percent | 0 percent | – | – | Medium | |||||

| 19 | The United States | 5.072.300 | 4 percent | 4.247 | 0 percent | – | – | Medium | Advanced | High | Recycling Center for American Continent Research Center |

| 20 | European Union | 4,796,300 (Finland) 1,534,900 (Sweden) 72,900 (Spain) 60,400 (Norway) | 4 percent 1 percent 0 percent 0 percent | 3,217,400 (Greece) 100,800 (Poland) | 2 percent 0 percent | – | – | Stringent | High | Recycling Center in one of Countries in EU. Refurbish Center |

It is essential for the G20 to develop a standard CEB framework policy and ensure each member state has CEB regulations. The regulatory framework should accommodate private sector incentives to accelerate the implementation of the CEB since these recycled materials would reduce by 38 percent the CO2, emitted in the production process and which could initiate the establishment of a green battery industry. In the near term, a detailed assessment to identify the battery-recycling target would be the key recommendation for the G20 to undertake.

G20 members could develop a roadmap and play an essential role in developing collaborative action that supports each other. The main framework could be done collaboratively by:

- Enabling the ecosystem by removing barriers, providing skills and information.

- Engaging with the media, social promotion, social activities and voluntarily action by the private sector to support the CEB.

- Encouraging the CEB through tax cuts for recycling companies, grants for research, subsidies or incentives for battery production that supports the CEB ecosystem.

- Enforcing the step-by-step regulation and policy, towards a stringent ecosystem.

In order for the G20 to develop a CEB, the collaboration should take into consideration:

- Sustainable mining and refining procedures to ensure safety and environmental sustainability.

- Providing the manufacturing companies and countries with assistance:

- Taking the recycled product which in percentage terms increases yearly.

- Information on product design and de-assembly process

- Detailing product information and composition

- Providing services and refurbishment centres.

- Supporting research centre countries financially and openly to allow collaboration

- Enable the public/institution to be more responsible in utilising recycled and new batteries:

- Product registration with tracking of cycle (used – service – used – recycling as the end)

- Utilising battery until minimum level of performance

- Utilising the low-level performance batteries in the power-generation sector as additional energy storage to tackle intermittency.

- Ensuring the recycling company engages in a responsible, clean and green process; and responsible waste management.

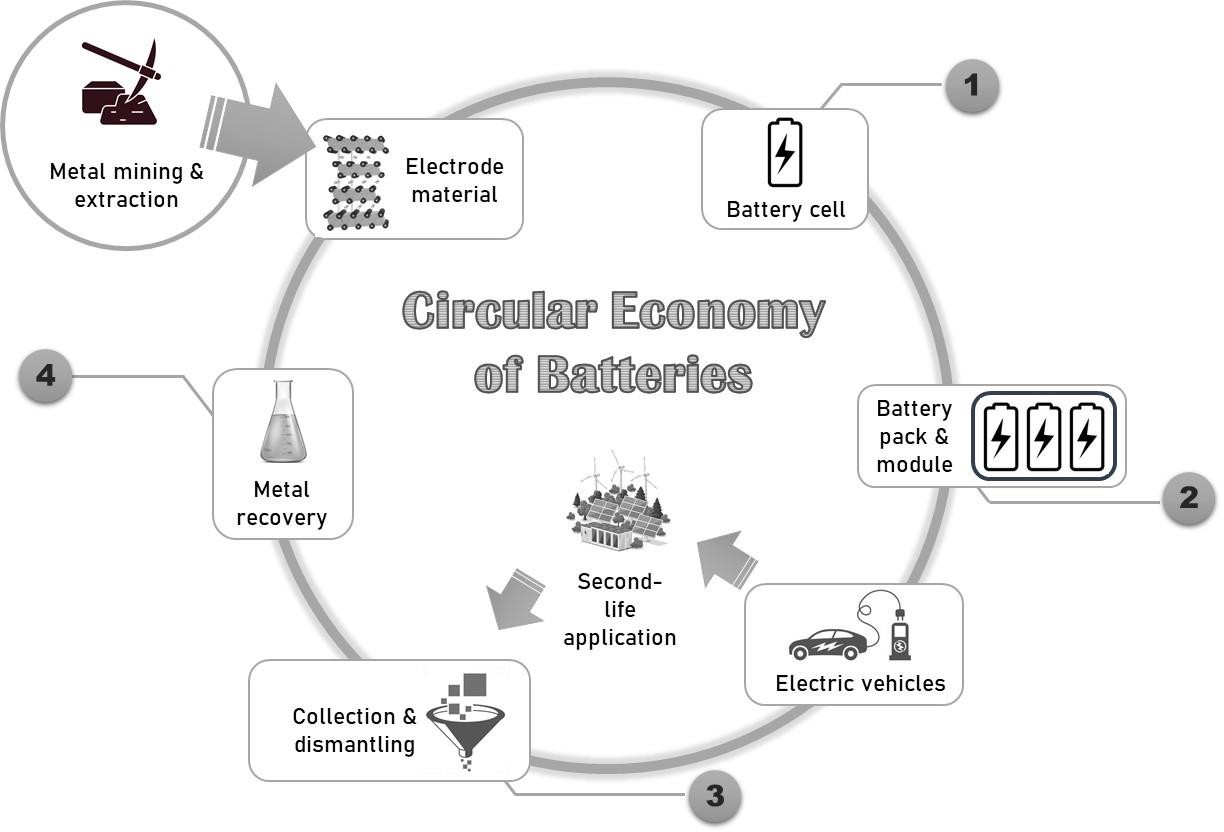

POLICIES TO SUPPORT CEB PROTOCOLS

Based on eight to 10 years of EV batteries’ life span (~20 percent degradation rate), 1 million EVs have now reached their optimum utilisation.15 The numbers will continue to grow significantly, accompanied by the ICE vehicle ban regulations in the G20 members.16 This situation should be anticipated since waste batteries from EVs are environmentally hazardous and harmful to human health. By enabling a CEB, the waste batteries can be (i) potentially used in second-life applications, for example, to support a renewable energy grid as stationary energy storage devices; for an additional 10 years before being recycled, and (ii) they can be recycled to obtain valuable materials, such as lithium, cobalt, nickel, copper, aliminium, etc., for new battery production. The average content of lithium is approximately 5 wt. %; this value is higher than the content in natural ores.17

For second-life applications, after disassembling from packs, used batteries should also be tested to identify their state of health for determining their reusability before reconfiguration and reassembly. On the other hand, waste battery-recycling technologies are challenging, although there are existing battery-recycling technologies such as direct recycling, pyrometallurgy and/or hydrometallurgy.18 In the pyrometallurgical recycling method, high- temperature thermal treatments are used, which can remove flammable electrolytes and decompose organic components in the separator layer; however, high energy consumption and the emission of hazardous gases are the primary concerns. Besides, the hydrometallurgical recycling method offers several advantages, including lower energy consumption and a potentially smaller environmental footprint.

Implementing both options to treat waste batteries, i.e., use for second-life applications and recycling, requires sufficient knowledge and technologies. Some G20 member states and companies have established the protocols and technologies and paid massive attention to that situation. For example, the EU Battery Directive has developed legislation on batteries

and waste batteries.16,19,20 Unfortunately, on the other hand, the other member states, although they are vast battery consumers, are still in the early stage of development for treating waste batteries. Therefore, The G20 should encourage and accelerate its member states to pay special attention to this issue and establish related policies for it.

Figure 1. General protocols for CEB.

The general protocols for CEB are presented in Figure 1. The numbers indicate the issues to which the G20 should pay attention. In the initial stage, the G20 should establish a special battery initiative division to set a CEB target and develop and standardise a protocol framework for waste battery treatment. (1) The G20 member states should act upon the standardised protocols and encourage the relevant stakeholders, particularly battery manufacturers, to comply with extended producer responsibility principles and set up waste battery collection systems. (2) Battery pack and module companies should also be encouraged to design modules that exhibit a low-cost disassembly process. (3) To ensure an effective process, the informal and private sectors should be activated, and proper knowledge should be facilitated by local governments of the G20 member states. Specific regulations related to the battery collection points should also be developed. (4) The standardised waste battery treatment protocols should cover the technicalities and environmental assessment that will be used as a fundamental guideline for CEB players in each member state.

ACCESS TO FINANCE AND INVESTMENT OF BATTERY RECYCLING

To proceed with the effective CEB scheme design, the scheme needs to be designed to achieve its objectives in a cost-effective manner with a consistent and efficient incentive structure. The most significant barrier for the implementation of CEB design is the high cost of collecting, sorting and recycling, particularly in the larger countries within the G20, such as Australia, China and Indonesia. To ensure that the implementation of the CEB is effective, the CEB needs to be supported by robust financial support. In this policy brief, we propose a battery levy and rebate mechanism for CEB implementation among G20 members. The levy is specifically designed for battery producers. While the rebate is intended to promote market participation and innovation. Implementing levies and rebates will improve the efficiency and viability of the battery-recycling sector.

As proposed, the annual levy for battery producers would be a proportion of the total amount of funds that need to be paid as part of the battery producer’s responsibility. The total size of levy varies by industry, which is determined based on the annual weight of batteries produced. It is assumed that the total weight of the battery excludes packaging, housing and circuitry. The collected funds from the producer levy will be used to operate the CEB and pay a rebate for the recycling process. The intent of the rebate is to encourage participation and innovation in the market in order to improve the efficiency and viability of the battery-recycling sector.

In addition, to ensuring the CEB works properly, the monitoring and evaluation in every year will be provided to indicate whether adjustments are required for the levy rate if needed. The government or the chosen organisation will closely monitor levy rates and rebates to ensure the implementation meets the objectives. The annual monitoring and evaluation would also be published on a website to provide transparency and attract investment from the private sector. Currently, efforts to conserve precious metals in batteries have been introduced in several countries. Australia, a G20 country, has recently launched the Battery Stewardship Council (BSC). The BSC was established to manage batteries from the production design to their end of life, with the participation of battery producers, consumers and accredited retailers and waste-processing facilities. The BSC was launched in early 2022 with the goal of significantly increasing battery collection and recycling. Levies and rebates are also part of the financial mechanism proposed in the BSC.

COLLABORATION PLATFORMS FOR CEB

The circular economy will improve economic sustainability by extending the value of materials and resources and reducing natural-resource extraction and waste production. However, enabling a circular economy demands significant transition technologically and socially; this systemic change requires multiple actors to collaborate and create the circular economy ecosystem.21 Thus, creating a sustainable battery supply chain is difficult without collaboration between multiple actors, including governments, the manufacturing industry, battery distributors, battery-recycling companies and the general public.

A CEB ecosystem should be created at the global level; this is because the raw materials of batteries originate from several countries, and the battery market is worldwide. For instance, although China is predicted to be the country with the largest production of lithium-ion batteries,22 the raw materials come from many countries, and the battery application is also worldwide as presented in Table 1. Therefore, relying on a few countries and companies would not be adequate to create a whole CEB ecosystem. Enhancing international collaboration is essential to accelerate technology deployment and cost reduction in the global supply chain of batteries.

A collaboration platform is necessary to support the acceleration of the CEB ecosystem. The purpose of this platform is to accelerate the development of sustainable battery technologies; improve the capacity of the battery industry (technologies, materials and workforce) to satisfy the future battery demand; advance battery-recycling technologies and processes, as well as improving battery material recovery; ensure environmental safety from hazardous battery waste; and reduce the cost of processing and utilising battery waste, as well as increasing its economic value. This platform would trigger the actors in the CEB value chain to adopt a CEB.

Collaboration between organisations exists and has been practiced recently. For instance, the cooperation between the European Battery Alliance and the US Li-Bridge Alliance, which also received support from the EU Commission and the US Department of Energy. This cooperation aims to “accelerate development of robust supply chains for lithium-ion and next generation batteries, including the critical raw materials segments”.23 This collaboration could be expanded at the G20 level to have more global impact.

As the world’s world-leading economies, the members of the G20 have an interest in enabling the CEB ecosystem in order to satisfy battery demand for their countries, as well as preserve raw materials in the future. Thus, a special task force or division for the CEB initiative should be established by the G20 forum to scale up the implementation of efficient CEB regulation, technological development and financing mechanisms for the battery- recycling business.

References

- I.E. Nikolaou, K.P. Tsagarakis, An introduction to circular economy and sustainability: Some existing lessons and future directions, Sustainable Production and Consumption, 28 (2021) 600

- M.V. Barros, R. Salvador, G.F. do Prado, A.C. de Francisco, C.M. Piekarski, Circular economy as a driver to sustainable businesses, Cleaner Environmental Systems, 2 (2001) 100006

- A. Chaudhari, Circular Economy: How it can contribute to sustainable development, EARTH5R, accessed on June, 29, 2022, URL: https://earth5r.org/circular-economy- can-contribute-sustainable-development/

- Y.M. Alshammari, Achieving climate targets via the Circular Carbon Economy: The case of Saudi Arabia, Journal of Carbon Research, 6 (2020) 54

- L.M. Alsarhan, A.S. Alayyar, N.B. Alqahtani, N.H. Khdary, Circular Carbon Economy (CCE): A way to invest CO2 and protect the environment, a review, Sustainability, 13 (2021) 11625

- T20 Statement on the Circular Carbon Economy, accessed on June, 29, 2022, URL: https://www.g20.utoronto.ca/t20/2020-CCE_Statement.pdf

- S.K. Bakshi, S. Bhattacharjya, R.A. Meidl, A G20 Circular Carbon Economy: Policies and practices to foster circularity in plastics, TF2: Climate Change and Environment, T20 Saudi Arabia 2020

- N.Y. Mansouri, A. Alhusseini, N.T. Al-Saud, M.S. Alshalan, M. Benlahrech, Y. Kobayashi, R. Sedaoui, M. Toyoda, L. Yaroshenko, A carbon management system of innovation: Towards a Circular Carbon Economy, TF2: Climate Change and Environment, T20 Saudi Arabia 2020

- A. Bouloukos, S. Lechtenberg-Kasten, M. Wang, Plastics in a Circular Carbon Economy, TF2: Climate Change, Sustainable Energy & Environment, T20 Italy 2021

- M. Stecca, L. R. Elizondo, T. B. Soeiro, P. Bauer and P. Palensky, “A comprehensive review of the integration of battery energy storage systems into distribution networks,” IEEE Open Journal of the Industrial Electronics Society, 1 (2020) 46

- A vision for sustainable battery value chain in 2030: Unlocking the full potential to power sustainable development and climate change mitigation, World Economic Forum, 2019

- C. Xu, Q. Dai, L. Gaines, M. Hu, A. Tukker, B. Steubing, Future material demand for automotive lithium-based batteries, Communications Materials, 1 (2020) 1

- E. Fan, L. Li, Z. Wang, J. Lin, Y. Huang, Y. Yao, R. Chen, F. Wu, Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects, Chemical Reviews, 120 (2020) 7020

- K. Schierle-Arndt, Battery recycling: Closing the loop in e-mobility, Battery Circular Economy, Stanford StorageX International Symposium, 2022

- Bazant et al., End-of-life or second-life options for retired electric vehicle batteries, Cell Reports Physical Science, 2 (2021) 100537

- Carlier, Battery electric vehicles in use – worldwide 2016-2020, Statista, 2021

- Malefant et al., Recycling electric vehicle batteries: ecological transformation and preserving resources, Field Actions Science Reports. The Journal of Field Actions, 23 (2021) 74

- Luo et al., The current process for the recycling of spent lithium ion batteries, Frontiers in Chemistry, (2020) 1027

- Wang et al., Recycling end-of-life electric vehicle lithium-ion batteries, Joule, 3 (2019) 2622

- European Commission, Batteries and accumulators https://ec.europa.eu/environment/topics/waste-and-recycling/batteries-and- accumulators_en

- Aarikka-Stenroos, L., Thomas, L. D. W. (n.d.). Circular economy ecosystems: a typology, definitions, and implications. In P. Ritala (Ed.), Research handbook of sustainability agency (pp. 260–276).

- Yu, A., Sumangil, M. (2021, February 16). Top electric vehicle markets dominate lithium-ion battery capacity growth. S& P Global. Retrieved on April 25, 2022, from https://www.spglobal.com/marketintelligence/en/news-insights/blog/top-electric-vehicle-markets-dominate-lithium-ion-battery-capacity-growth

- Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs. (2022, March 14). European Commission and U.S. Department of Energy Support Collaboration between the European Battery Alliance and U.S. Li-Bridge Alliance to strengthen supply chain. European Commission. Retrieved on April 20, 2022, from https://ec.europa.eu/growth/news/european-commission-and-us-department- energy-support-collaboration-between-european-battery-alliance-2022-03-14_en